What is Print Thick Film heater?

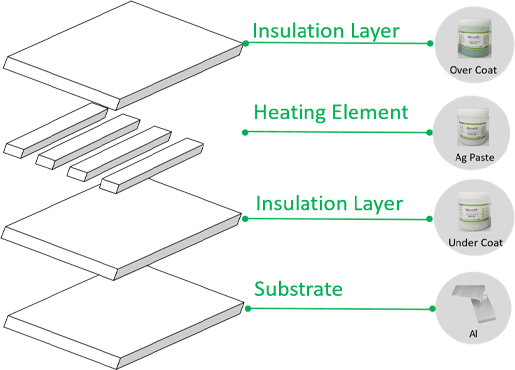

This is a printing heater made by stacking insulating ink, heating ink, and electrode ink on the substrate in the area where heat is desired.

- Insulation ink suitable for plate-type materials such as SUS&Al

- High heat-resistant electrode ink and high-temperature heating ink

- Insulation protection ink to protect the heating area

- Assembly part electrode connection terminal - Soldering, Bolting, Adhesive & Molding, Spring, Welding, Blazing

Major development areas

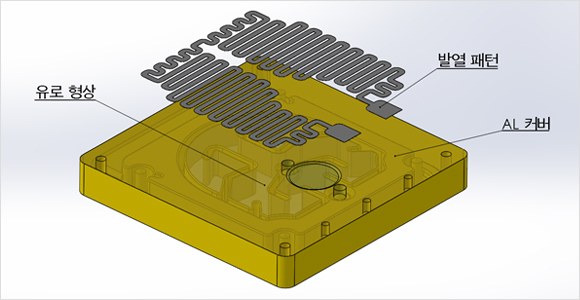

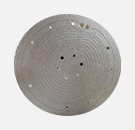

Aluminum printing heater

semiconductor manufacturing equipment, MLCC aging heater, food dryer heater, drying furnace, air heater, etc.

Manufacturing process

-

Heating paste & High insulating paste

-

Pattern design

-

Screen engraving

-

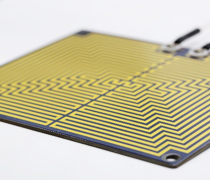

Printing line

-

heater

- Prepare heating paste and insulating paste respectively.

- After designing the pattern according to the heating temperature, screen engraving is performed according to the desired specifications.

- After repeating printing and drying several times, a printed thick film heater integrated into the substrate is manufactured.

Advantages

Paste manufacturing for heater

- Insulation Paste

- Resistor Paste

- Conductor Paste

- Sensor Paste

We directly manufacture the above 4 types of ink and apply it to our products.

-

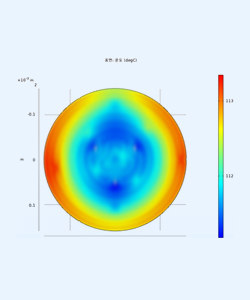

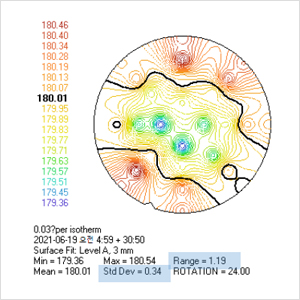

temperature simulation

-

Sensarray test

Uniformity

- Through adjusting the pattern spacing and optimizing the printing, 182.5 ±1.5℃

- Reduced the deviation between the outer and inner parts

| Wire heater | Print heater Ex1) | Print heater Ex2) | |

|---|---|---|---|

| Product picture |  |

|

|

| Reached Temp | 150℃ | 150℃ | 150℃ |

| Reached time | 5min30sec | 5min20sec | 5min30sec |

| 150℃ Reached power consumption |

65W | 52W (19.9%) | 53W (18.4%) |

| Power per hour | 129W | 129W (0.4%) | 120W (7.3%) |

Energy efficiency

- Increase energy efficiency by optimizing printing and resistance

- Example 1) shortened the arrival time compared to the wire heater

- Example 2) reduced power consumption compared to the wire heater.

Efficiency can be increased even more when applying insulation

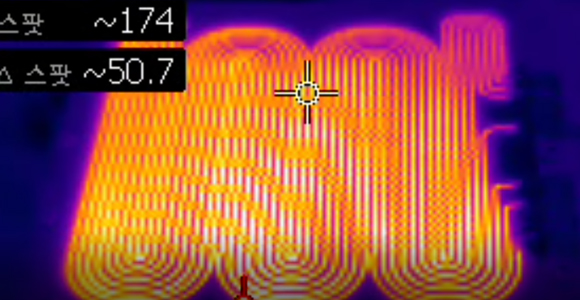

High power

- With the technology to control the print pattern and thickness, it is possible to easily manufacture a heater with high power.