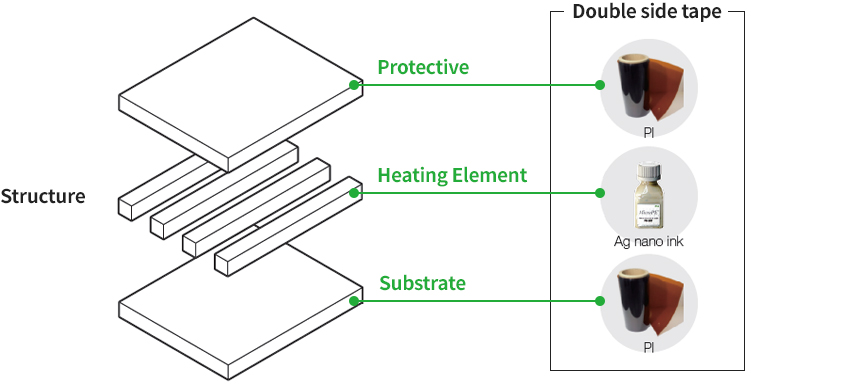

What is Printed Film Heater?

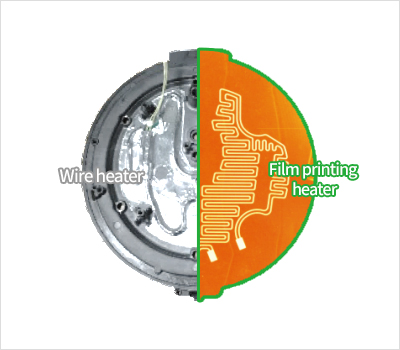

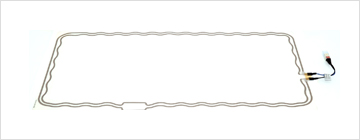

- Design the conductive pattern for heating element based on Ag ink.

- Print the desired pattern and connect the electrodes.

- Substitute a thin film instead of a thick wire.

- Easy assembly, easy to fix with adhesive film.

-

PET Film Printed Heater

-

PI Film Printed Heater

-

TPU Film Printed Heater

Advantages

- Uniform

- Efficiency

- Economics

- Safety

- Simplification of manufacturing

- Free pattern design

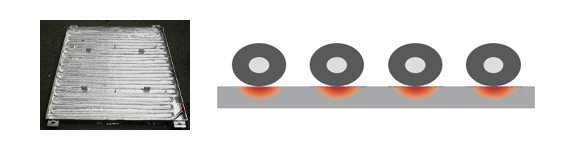

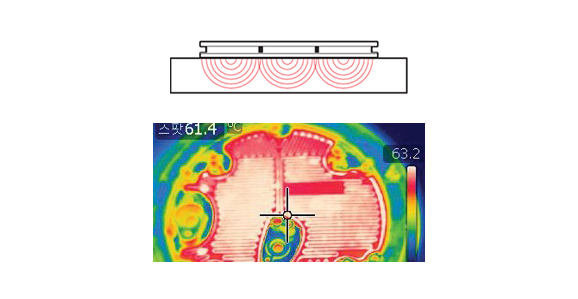

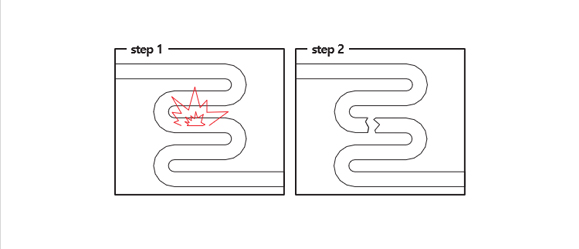

Uniform

-

Starts to heat up for Printed film heater

-

Starts to heat up for Wire heater

- Conventional wire heaters start with some heat when they start to heat up, so their efficiency is low, but printed film heaters are applied to thin films so that heat transfer is more even.

*Variable according to conditions

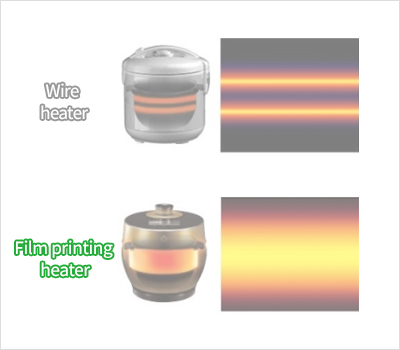

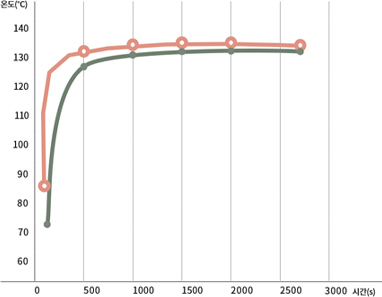

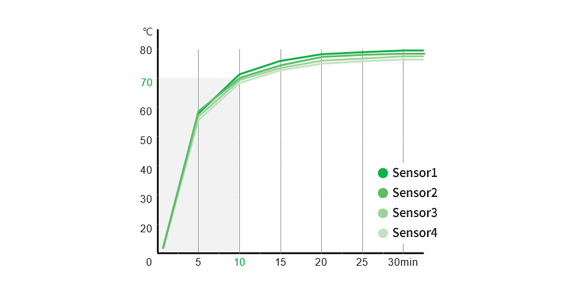

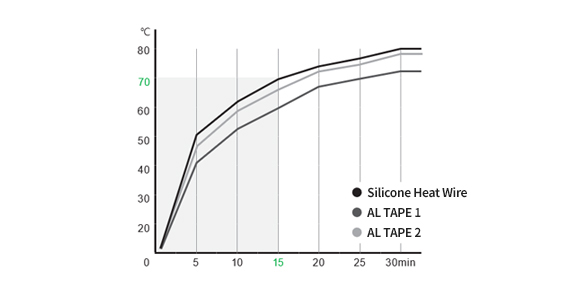

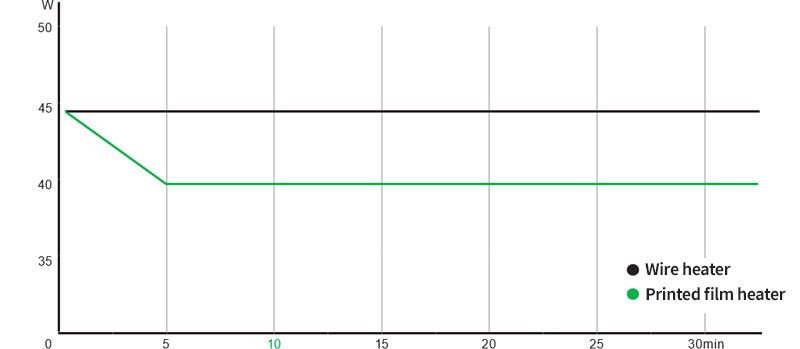

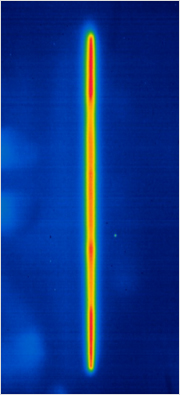

Efficiency

-

Temperature by sensor of printed film heater

-

Temperature by sensor of wire heater

- It heats up quickly as of the large heating area and the excellent conductivity of silver, the metal used.

- For example, under the test condition to reach 70℃, it takes 15 minutes for the wire but 10 minutes for the printed film heater, which means 5 minutes time saving.

*Variable according to conditions

Economics

- Resistance increase and power consumption decrease

- Our heating element can be reduced the power

- Energy saving effect is more than 10%

*Variable according to conditions

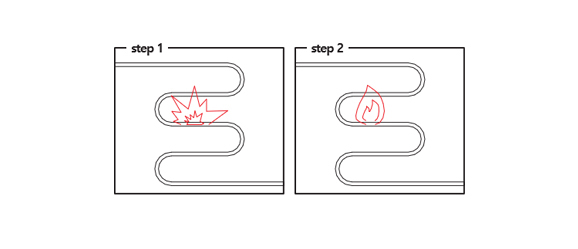

Safety

-

Printed film heater

-

Wire heater

| Safety comparison | Printed film heater | Wire heater |

|---|---|---|

| In case of Overvoltage Issue | 500V Disconnection | 550V Smoke, 600V Fire |

| Over temperature | PET: 250℃ PI: 350℃ |

PVC Wire sheath 150℃ Fire Silicon Wire sheath 300℃ Fire |

| Malfunction | Heat wire break due to film shrinkage | The coating melts and heat is transferred to other objects |

- The heat resistance temperature is 100℃ higher than PVC general wire

- When the limit temperature is exceeded, the film shrinks and breaks, preventing fire and has Self-Fuse function as it does not ignite and is disconnected at 250℃

*Variable according to conditions

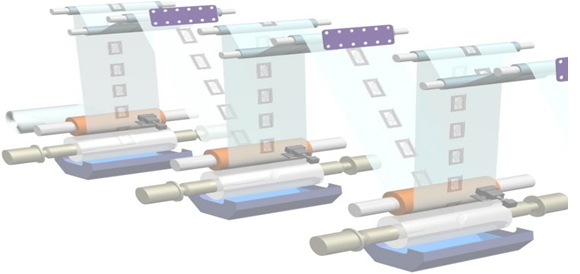

Simplification of manufacturing

Roll Print

| Process/Index | Roll Print | Screen Print | Wire for Heat | Aluminum etching |

|---|---|---|---|---|

| 1 | Print (Silver Nano) | Print (carbon) | Draw &Extrude | PET aluminum film |

| 2 | Heat dry | Heat dry | Strand | Form resist |

| 3 | Print(silver) | Isolation | Dry | |

| 4 | Heat dry | Union | Exposure | |

| 5 | Sheath | Status | ||

| 6 | Arrange on aluminum tape | Dry | ||

| 7 | Etching | |||

| 8 | Resist strip | |||

| 9 | Rinse | |||

| 10 | Print screen carbon | |||

| 11 | Heat dry | |||

| Level | Level 2 | Level 4 | Level 6 | Level 11 |

- In the existing carbon heating element printing method, the electrode layer and the heating element layer were separated and printing had to be performed twice. However, the gravure printing method using silver Nano ink printed the electrode layer and the heating element layer at the same time to simplify the manufacturing process.

*Variable according to conditions

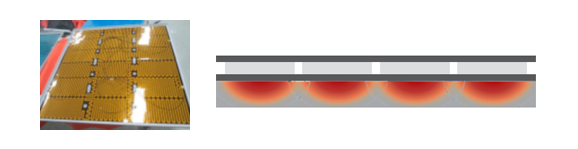

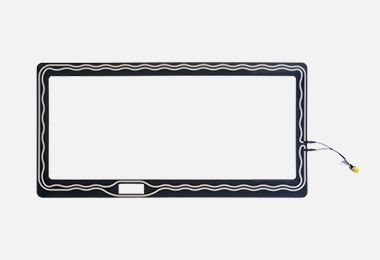

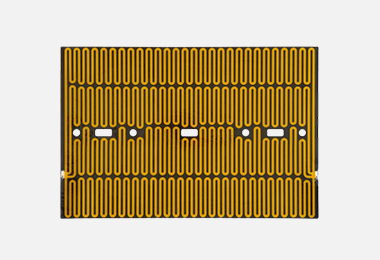

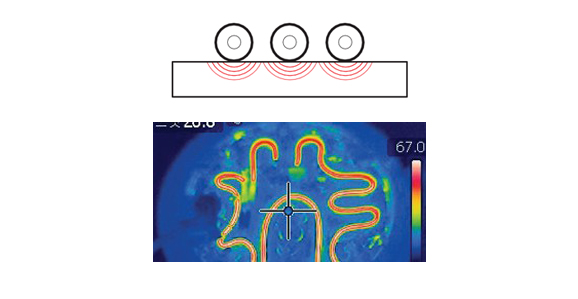

Free pattern design

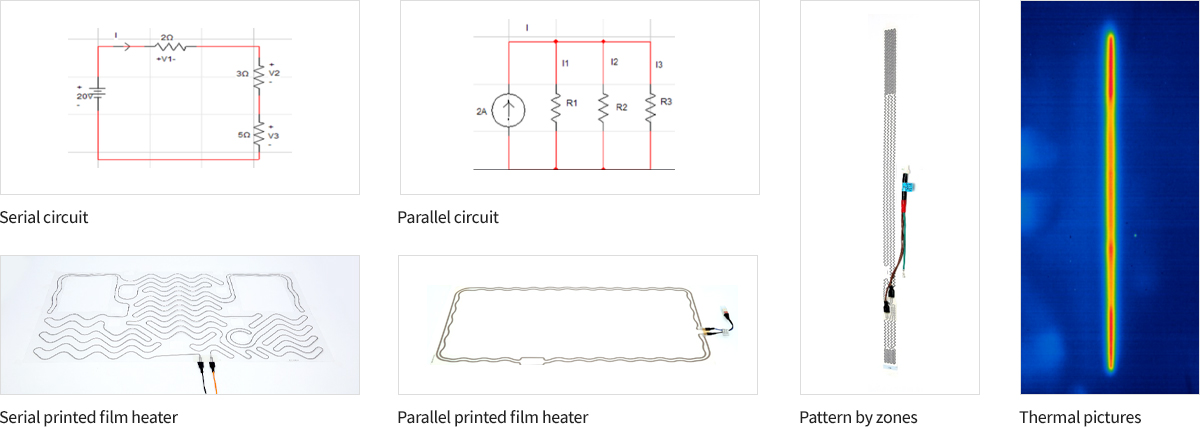

Serial circuit

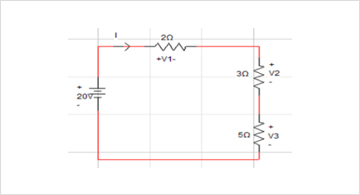

Parallel circuit

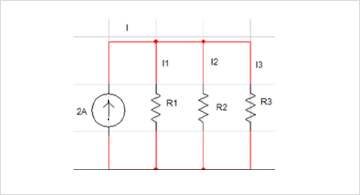

Serial printed film heater

Parallel printed film heater

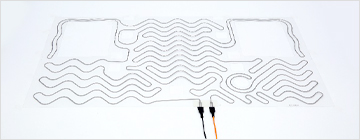

Pattern by zones

Thermal pictures

- Since the silver print pattern is freely available, both parallel circuits and series circuits are possible.

- And by adjusting the spacing and thickness of the pattern, the heat is distributed by varying the pattern for each zone.